SEARCH

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

At Guangzhou’s “Greater Bay Area, Mega Shipping, Collaborative Growth” Port Economy Summit, Nansha unveiled ¥7B in signed projects and launched two pivotal platforms: the Greater Bay Area Port Industry Cluster and Shipping Joint Trading Center, marking its leap toward a high-energy port economy.

The “Five-Port Synergy” blueprint (Seaport, Airport, Digital Port, Financial Port, Talent Port) accelerates, fueling trillion-yuan port-industrial clusters via global shipping hubs.

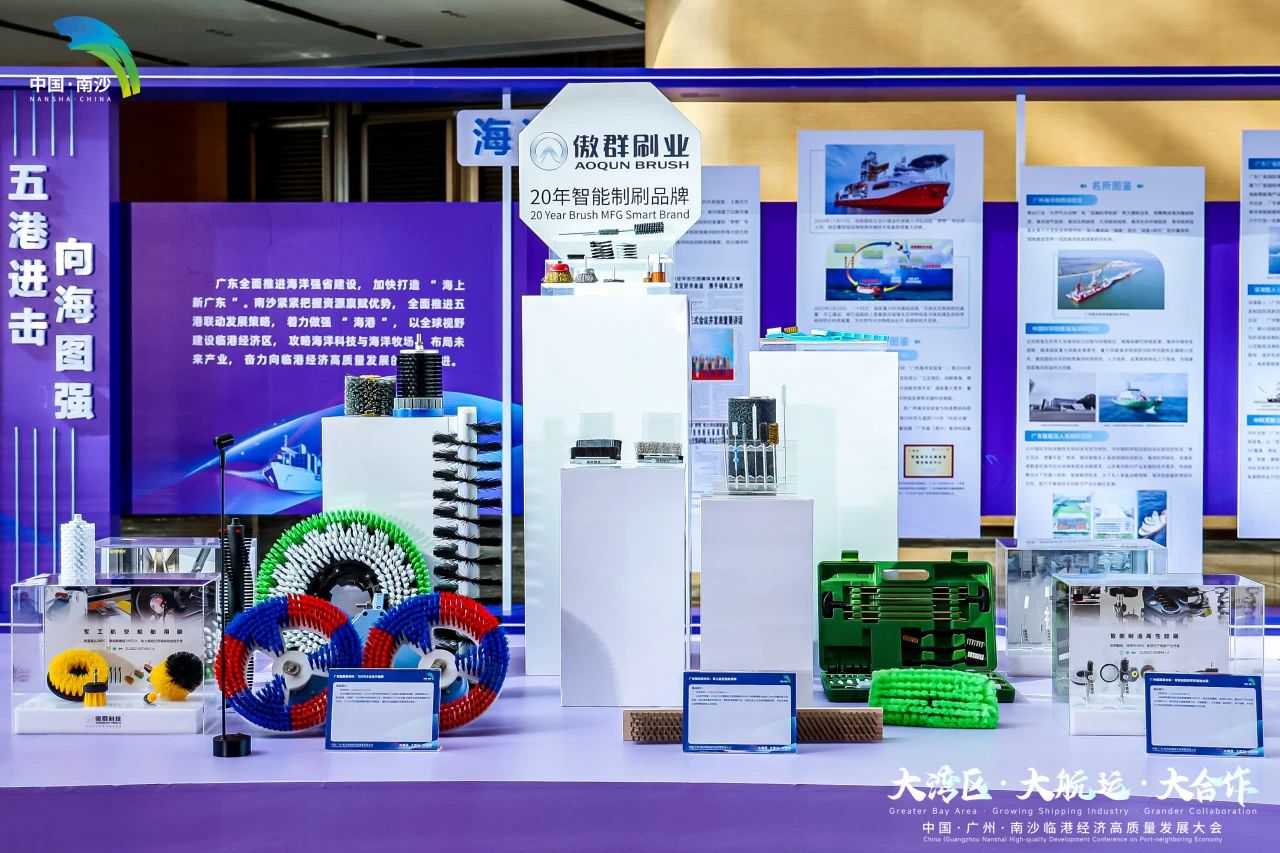

Amid this maritime industrial surge, AOQUN aligns with core port economy sectors through its “One Core, Multiple Innovations” product matrix:

High-Performance Brush for Smart Manufacturing (Patent: ZL202210598941.4)

1M+ friction cycles, 2× polishing efficiency, 99.96% yield

IATF16949 certified; replaces EU/US/JP tools

Applications: Shipbuilding, automotive, aerospace, semiconductors

Military/Aviation/Marine Brush (Patent: ZL202210598941.4)

98.7% carbon removal (turbine blades); 3.2mm groove cleaning

45% less downtime; replaces monopolized imports

Applications: Warship turbines, military aircraft engines

eVTOL Energy-Saving Brush(Patent: ZL202411844819.6)

98.5% air-tightness against turbulence/high-temp dust

40% energy reduction; 30+ aviation certifications

Breakthrough: Zero-leakage at wing-fuselage joints

With innovative materials, precision engineering, and smart brush solutions, AOQUN drives advanced manufacturing, biopharma, clean energy, and precision processing—powering the Greater Bay Area’s maritime-industrial ascent.

The full moon shines over the courtyard, deepening the Mid-Autumn ambiance.Eighteen years of companionship, as heartfelt as ever.AOQUN Brush Industry’s themed event,“AOQUN's Hometown Sentiments, Shared Mid-Autumn Moon,” kicked off in a warm a...

View detailsAt the 138th Canton Fair, AOQUN Brush made a grand appearance with its upgraded intelligent brush series, leveraging millimeter-level precision and AI-enabled technology to position the brush as a key enabler of New Quality Productivity. ...

View detailsAt TSMC’s 3nm production line, a mere 0.5-micron particle can destroy wafers worth millions. SEMI data reveals that global semiconductor fabs suffer $5 billion+ annual losses due to yield gaps from cleaning processes—a stark testament to nanoscal...

View detailsDuring the 2025 National Two Sessions, new materials emerged as a strategic pillar for achieving China’s dual-carbon goals and driving industrial upgrades. Breakthroughs in perovskite photovoltaic cells have redefined efficiency benchma...

View details