SEARCH

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

A great nation prospers, blessing the vast land of China.Allies across the seas join in safeguarding the fullness of the moon.Seventy-six years of weathering storms and braving hardships,Seventy-six years of blooming springs and fruitful autumns.Across the nine provinces, flowers bloom in splendid contention,Under the endless sky, stars and...

The full moon shines over the courtyard, deepening the Mid-Autumn ambiance.Eighteen years of companionship, as heartfelt as ever.AOQUN Brush Industry’s themed event,“AOQUN's Hometown Sentiments, Shared Mid-Autumn Moon,” kicked off in a warm and welcoming atmosphere. During the Mid-Autumn Festival, Liu Xuezhen, Founder and Genera...

Golden September, gathering in Mexico CityThe China (Mexico) Export Brand Joint Exhibition blooms in splendorAOQUN Brush IndustryConnects global markets with smart brush manufacturingShowcasing to American clients The innovative strength and exceptional quality of Chinese brands At the exhibition, AOQUN prominently displayed a serie...

2025 Suzhou Medical Device Innovation ExpoMedical Fair China (MFC)Dates: August 21-23Venue: Suzhou International Expo Center Guangzhou AOQUN New Material Co., Ltd. At this Medical Device Innovation Expo, AOQUN Brush Industry will showcase its core products, including cell sampling brushes, new antibacterial brushes, wear...

At TSMC’s 3nm production line, a mere 0.5-micron particle can destroy wafers worth millions. SEMI data reveals that global semiconductor fabs suffer $5 billion+ annual losses due to yield gaps from cleaning processes—a stark testament to nanoscale manufacturing’s zero-tolerance for contamination.

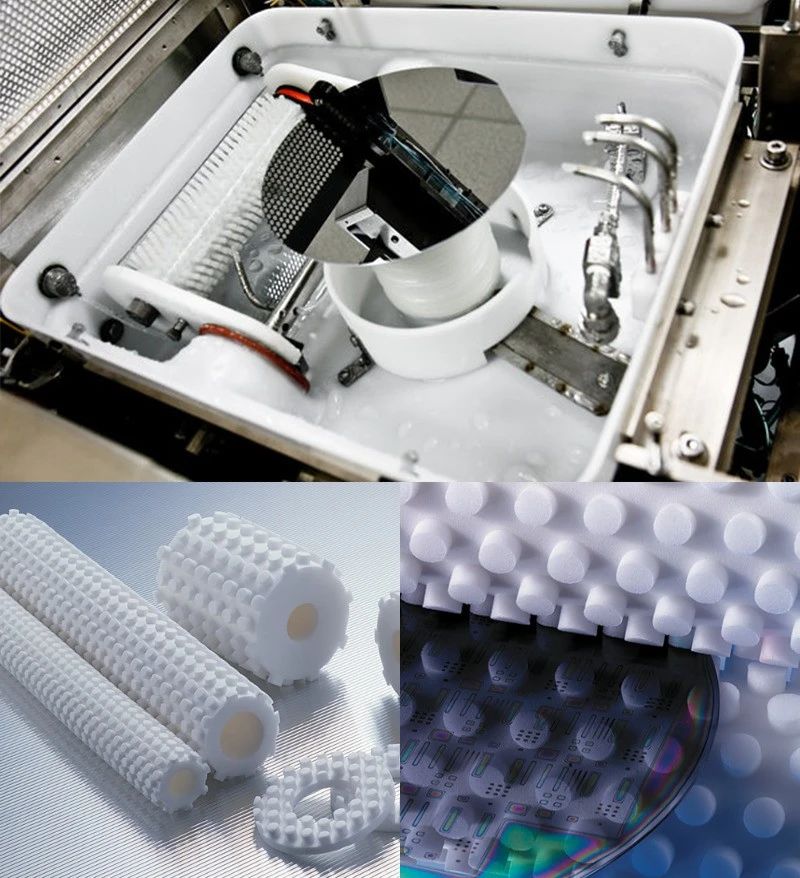

AOQUN’s Engineering R&D Center, backed by 20 years of expertise and partnerships with Sun Yat-sen University, Jinan University, and others, has pioneered the Intelligent Damage-Free Wafer Cleaning Brush (Patent: ZL202411907351). This “nano vacuum“-like solution empowers the semiconductor industry to shatter cleaning barriers.

▶ Zero-Damage Precision

▶ Revolutionary Contaminant Removal

Eliminates stubborn residues (CMP slurry, metal debris) through directional fiber alignment technology, ensuring uniform pressure distribution. This achieves:

✓ 40% higher cleaning efficiency

✓ Zero surface damage

✓ Replaces German/EU/Japanese polishing tools

AOQUN’s wafer/chip cleaning solutions span:

With 250 million annual capacity, AOQUN meets high-volume, high-precision demands of global semiconductor leaders.

AOQUN will advance material science and digital production to tackle cleaning challenges in sub-nm processes and high-frequency applications—empowering the IoT era with micron-perfect purity.

In laboratories at Stanford University School of Medicine, a 0.8mm-diameter cell sampling brush accomplishes the once-impossible: capturing 1.5 million viable cells from cervical folds with millimeter precision—redefining the ...

View detailsIn modern defense industries, a pivotal statistic reshapes priorities: 70% of equipment efficacy hinges on cleaning precision. As the "Unseen Guardian," AOQUN leverages decades of military expertise to deliver advanced artillery brush & firea...

View detailsOn the opening day of the 2025 International Brush Industry Exhibition (CIBRUSH), AOQUN Brush Industry—a National "Specialized, Refined, Distinctive, and Innovative" Little Giant enterprise and a leading smart brush manufacturing brand—formally c...

View details2025 Suzhou Medical Device Innovation ExpoMedical Fair China (MFC)Dates: August 21-23Venue: Suzhou International Expo Center Guangzhou AOQUN New Material Co., Ltd. At this Medical Device Innovation Expo, AOQUN Brush Indust...

View details